Are you looking for an essay on the ‘Types of Biogas Plants’? Find paragraphs, long and short essays on the ‘Types of Biogas Plants’ especially written for school and college students.

Essay on Biogas Plants

Essay Contents:

- Essay on Continuous Type Biogas Plant

- Essay on Batch Type Biogas Plant

- Essay on Floating Drum Type Biogas Plant

- Essay on Janata Model Biogas Plant (Fixed dome)

- Essay on Deenbandhu Biogas Plant (DBP)

Essay # 1. Continuous Type Biogas Plant:

In this type of plant the biomass is fed regularly to the digester and it supplies the gas continuously.

These are two types of continuous biogas plant:

i. Single stage type

ii. Two stage type

i. Single Stage Continuous Biogas Plant:

In this type of plant, the entire processes of conversion of biomass into biogas are carried in a single digester. This chamber is regularly fed with the raw materials while the spent residue keeps moving out.

Advantages:

a. Simple in construction.

b. It does not need skilled labour.

c. It is easy to operate and control.

d. These are preferred for small and medium sized biogas plants.

Serious problems are encountered with agricultural residues when fermented in a single stage continuous process.

ii. Two Stage Continuous Type Biogas Plant:

These plants have two digesters for digestion of biomass. In the ‘first digester’ the biomass is fed in which the acid production is carried out and then only dilute acids are fed into the ‘second digester’ where bio-methanation takes place and biogas can be collected from the second digester / chamber.

Advantages:

a. It produces more gas than the single stage plants.

b. It requires lesser period of digestion as compared to single stage plants.

c. These plants are preferred for large size biogas plants.

Advantages of Continuous Type Biogas Plant:

Following are the advantages of continuous type biogas plants:

a. Continuous gas production.

b. Less retention period.

c. Small digestion chambers required.

d. Less problems as compared to batch type plants.

Essay # 2. Batch Type Biogas Plant:

In a batch type plant, the biomass feeding is done in batches with large time interval between two consecutive batches.

A batch loaded digester is filled to its capacity and given sufficient retention time (35 to 45 days) for digestion of biomass. After the completion of digestion, the residue is emptied and filled again. Gas production is ‘uneven due to slow start of bacterial digestion and to overcome this difficulty, several digesters are used which are fed and emptied in sequential manner. Thus, the regular supply of gas is maintained.

The salient features of batch type plant are:

a. Gas production uneven/intermittent, depending upon the cleaning of the digester.

b. Several digesters required, to get continuous supply of gas.

c. High space requirements, due to several digesters.

d. High initial cost, due to large volume of digester.

e. Needs addition of fermented slurry to start the digestion process.

f. Operational and maintenance problems.

Essay # 3. Floating Drum Type Biogas Plant:

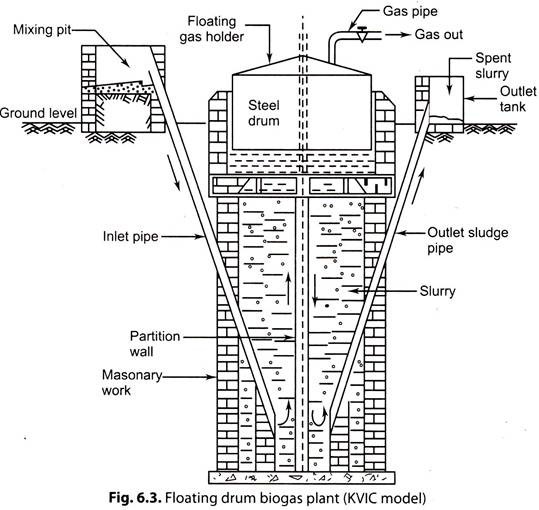

Khadi Village Industries Commission (KVIC) standardised a model in 1961 (Fig. 6.3). It consists of an underground “cylindrical masonary digester” having an “inlet pipe” for feeding animal dung slurry and an “outlet pipe” for sludge.

There is a “steel dome” for gas collection which floats on slurry. It moves up and down depending upon accumulation and discharge of gas guided by the domeguide itself. A “partition wall” provided in the digester improves circulation, necessary for fermentation.

A pressure of about 100 mm of water column is built in the “floating gas holder”, which is sufficient to supply gas upto 100 metres. This gas pressure also forces out the spent slurry through a sludge pipe.

Advantages of of Floating Drum Type Biogas Plant:

a. Gas pressure is constant.

b. Less scum problem.

c. No danger of explosion since there is no possibility of mixing of biogas and external air.

d No gas leakage problem.

Disadvantages of Floating Drum Type Biogas Plant:

a. High cost.

b. High maintenance cost.

c. There is a loss of heat through gas holder.

d. The outlet pipe, which should be flexible, requires regular attention.

Essay # 4. Janata Model Biogas Plant (Fixed Dome):

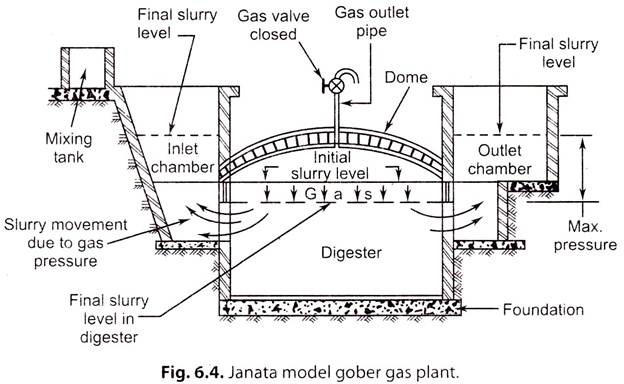

Constructional features. This plant consists of the following parts: (Refer to Fig. 6.4.)

a. Foundation

b. Digester

c. Dome

d. Inlet chamber

e. Outlet Chamber

f. Mixing tank

g. Gas outlet pipe.

a. Foundation:

The foundation is the amply compacted base of the digester made of cement concrete and brick ballast. Its construction is so carried out that it may provide a stable foundation to the digester walls and bear full load of slurry filled in the digester. It should be waterproof so that no percolation or water leakage takes place.

b. Digester:

It is underground cylindrical wall portion made of bricks, sand and cement. It is this place where fermentation of dung takes place. It is also sometimes called ‘fermentation tank’. Two rectangular openings facing each other are provided for inflow and outflow at almost middle of its height.

c. Dome:

It is a hemispherical roof of the digester; has a fixed height and forms the critical part in the construction of Janata gobar gas plant. The gas gets collected in the space of the dome and exerts pressure on the slurry in the digester.

d. Inlet Chamber:

An inlet chamber has a bell mouth shape and is made of bricks, cement and sand. It has its top opening at the ground level. Its outlet wall is made inclined/slopy to enable the daily cattle dung feed to move easily into the digester.

e. Outlet Chamber:

It is that part of the plant through which digested slurry moves out of the digester at a predetermined height. It has a small rectangular cross-section and above this it becomes larger to a defined height. For easy cleaning of the digester two steps are provided in it which enable a man to climb down. Its top opening is also at the ground level. Just near the top opening is provided a small outlet through which the digested/spent slurry flows to a compost pit.

f. Mixing Tank:

It is this tank where dung and water are mixed properly in the ratio of 1 : 1 to make slurry which is then poured into the inlet chamber.

g. Gas Outlet Pipe:

It is a small piece of G.I. Pipe which is fitted at the top of the dome for conveying the gas to the points of use. A valve is fitted at its end to regulate the flow of gas to the gas connections.

Site Selection:

While selecting the construction of Janata gober gas plant the following points should be given due consideration:

(i) The surface should be plane/even and be at a higher elevation so that during rainy season the water level is at least at 3 m depth. The higher level will discourage water logging and ensure easy discharge of spent slurry from the outlet chamber. Preferably this place should be beyond the reach of children.

(ii) The site should be as far as possible near the cattle shed and points of gas utilisation.

(iii) It should be at least 2 metres away from the foundation of the house/building.

(iv) The sun light should be available during whole of the day round the year.

(v) The site should be atleast 10-15 metres away from the any water drinking source.

(vi) There should not be any big tree near the plant whose roots may cause any harm with the passage of time.

(vii) There should be an easy availability of water near the plant.

(viii) To avoid carrying spent slurry to a very far distance there should be some space for making compost pit.

(ix) The earth should have adequate bearing stress to avoid any possibility of caving in or collapse of the plant.

Nature of Soil and Corresponding Precautions:

1. Soil Formed of Clay:

i. Related Problem:

Easy expansion and contraction of soil as the moisture content increases and decreases.

ii. Precautions:

Do not disturb the primitive soil; Or Take measures for excess or less of water; Or Drain the surface water.

2. Non-Uniform Soil Structure:

(e.g. partly soft soil and partly rocky)

i. Related Problem:

Crack may appear in digester wall due to uneven settlement.

ii. Precautions:

a. Provide a uniform kind of soil under the digester; Or

b. Remove a portion of the soft soil and put lime concrete and rubble in its place; Or

c. Remove a part of the rock and add medium and coarse sand, cinders, clay or clay gravel.

3. Soil with High Water Table:

i. Related Problem:

There is an upward force on the digester due to pressure of ground water.

ii. Precautions:

a. Construct the plant in low water seasons.

b. Dig a trench around the digester to collect the water; this water may be occasionally pumped out.

c. Divert the ground water, if possible, to other places e.g., well points.

d. Increase the strength of the base of the digester by increasing its thickness. It will counter act the buoyancy force of ground water.

Initial Loading of the Plant:

After completion of the plant it is to be charged with cattle dung and water in the ratio of 1 : 1. Since Janata Plant is designed for 50 days retention period, therefore initial loading will comprise of 50 times of gobar needed for daily feed. Naturally to arrange such a large quantity of gobar by farmers who have a few cattle is a problem. This difficulty can be overcome if the gobar is collected regularly during the period of construction of plant and by the time the plant is completed the large quantity of gobar collected can be then fed.

i. Before feeding into the digester the dung should be properly mixed with water in the ratio of 1 : 1 in the mixing tank to get the slurry.

ii. The slurry is then fed to the digester upto the step provided on the Outlet chamber. Thereafter the fermentation starts.

iii. Initially allow the gas which comprises of large percentage of a carbondioxide, oxygen and hydrogen sulphide to escape since it will not burn.

iv. The gas obtained after this release will have a right combination of methane (60%) and carbondioxide (40%) and burn with odourless blue flame in the gas chulha/burner/stove.

v. Now, at this stage start feeding the plant with dung slurry.

vi. Regular, proper and careful feeding will ensure flawless gas service.

Function of Plant:

i. The cattle dung and water are mixed properly in the ratio 1 : 1 to form slurry which is then filled in the digester upto the height of its cylindrical portion.

ii. As soon as the fermentation of dung picks up the generated gas starts accumulating in the dome. This gas then exerts pressure on the slurry and displaces it into the Inlet and Outlet chambers. Consequently the slurry level in the digester falls and rises in the Outlet chamber.

iii. This fall in the level of slurry continues (if the outlet pipe valve is closed) till the slurry level reaches the upper ends/edges of the Inlet and Outlet gates.

iv. After this stage any further accumulation of gas would exert pressure and start escaping through these gates into the atmosphere. This condition is indicated by bubbling and froth formation on the surface of the slurry in the inlet and outlet chambers.

v. The quantity of usable gas can be determined by calculating the increase in slurry volume in the inlet and outlet chambers.

vi. In the event of using gas the slurry level in the digester rises while that in the inlet and outlet comes down.

vii. The increase in gas pressure due to increased generation in comparison to its utilisation will push/displace the slurry up in the inlet and outlet chambers while the decrease in pressure is balanced by the return flow of slurry back in the digester.

viii. During the process approximately equivalent quantity of spent/digested slurry (top layer slurry) is discharged from the outlet chamber through the outlet opening; this is so because fresh/undigested slurry which is fed into the inlet chamber is heavier than the digested/spent slurry and settles down in the digester.

Chemistry of Gas Generation:

In this gas plant the feed which comprises mainly of cattle dung is subjected to anaerobic fermentation as a result of which is produced combustible gas and fully matured organic manure which is superior to green manure available from dung otherwise. The whole process of feeding slurry of dung and water and extraction of spent slurry in gobar gas plant is continuous one.

The cattle dung (and other fermentable materials like night soil, poultry or piggery droppings etc.) when confined in a place where there is no air gives rise to mainly two types of bacteria viz. Acid forming bacteria and Gasifying bacteria.

Acid forming bacteria convert carbohydrates, proteins, fats into volatile acids and carbon dioxide is produced during the process. This phase is also known as “liquification phase” and is brought about by a set of saprophytic bacteria by means of extracellular enzyme. These bacteria are less sensitive and can exist, develop and multiply in wide range of conditions.

Liquification phase is followed by “gasification phase” which is actively carried out by methane bacteria. They work upon volatile acid produced during the previous phase, with the help of intracellular enzyme and convert it into methane and carbondioxide.

The whole process of gas generation is governed by the factors viz. Temperature of substrate, Loading rate, Solid concentration, Detention period, pH value, Nutrients concentration and Toxic substances etc.

The composition of the gas produced varies with the type of fermentable material used. In case of cattle dung on an average the gas produced consists of 55 to 60% methane and 40 to 45% carbondioxide with little quantity of hydrogen, hydrogen sulphide. With night soil the percentage may be: Methane = 65%, carbondioxide 34%, hydrogen sulphide = 0.6% and other gas 0.4%.

Diphasic Anaerobic Digestion:

To tide over the problems generally associated with maintaining optimum fermentation conditions inside the digester, diphasic anaerobic digestion seems to be probable solution. In this system two separate digesters are used which separate the hydrogen and acid formation phases from methane formation phase; this separation of phases is brought out by kinetic control. The acid phase is operated at low retention times so that only the fast growing acidogens of first hydrolysis and acid forming stages are retained in the digester and methogens are washed out. The methane phase takes place in a separate digester with the acid phase effluent as the feed material.

This system facilitates provision of optimum environment conditions for growth of two physiologically different types of bacteria which in turn ensures higher efficiency of the process with subsequent reduction in the size of digester and their cost. In this process system monitoring is also rendered easier.

Acceleration of Gas Generation:

The gas production is usually satisfactory during summer season but it falls considerably during coldest months of the year.

The gas production can be enhanced / accelerated by following the tips given below:

(i) Add about 1 litre of cattle urine daily for every 5 kg slurry fed to the plant. It will augment the fermentation process and eventually increase gas production. The urine can be collected in the sump connected through a drain to the animal shed.

(ii) Feedback about 10% of the fresh spent/digested slurry to the plant. The microorganisms available in the spent slurry will stimulate fermentation.

(iii) Prepare the dung slurry with hot water. Water may be kept exposed to Sun during the day and be used in the evening to produce slurry. This process will prove helpful in increasing the temperature of slurry in the digester and subsequently actify the bacteria to generate more gas.

(iv) Cover the plant with rice straw or gunny bags during late evenings and nights; it will check fall of temperature and keep the bacteria active in gas generation.

(v) Add 1 kg of powdered leaves for every 50 kg dung fed to the plant; it will help creating warmer environment suitable to bacteria for actified fermentation.

(vi) Addition of poultry droppings (5 to 10%) and piggery waste helps to bring about increase in gas generation.

(vii) Provision of a compost pit around the plant assists in keeping the plant warm due to which gas generation is improved.

Advantages of Fixed Dome Type Plant:

1. No maintenance problems due to absence of moving parts.

2. Low cost.

3. Low operating cost.

4. Longer working life.

5. Due to underground construction, heat insulation is better and therefore, rate of gas production is uniform during night and day.

6. Quantity of gas produced is higher than movable drum type plants.

7. No corrosion problem.

8. Space above the plant can be used for other purposes.

Disadvantages of Fixed Dome Type Plant:

1. Variable gas pressure.

2. Gas production per cm3 of the digester volume is less.

3. Problem of scum formation.

4. For construction work skilled masons are required.

Essay # 5. Deenbandhu Biogas Plant (DBP):

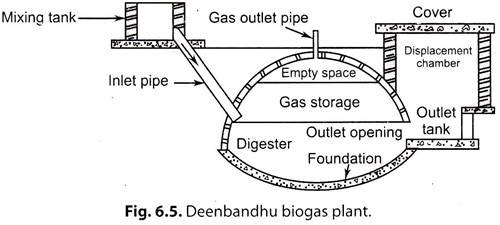

Refer to Fig. 6.5. This is fixed dome plant developed by Action for Food Production (AFPRO) in 1984. It is appropriate for all types of wastes and minimises biogas losses from inlet chamber.

Construction of Deenbandhu Biogas Plant:

It has ‘curved bottom’ and ‘hemispherical top’ which are joined at their bases with no cylindrical portion in between. An ‘inlet pipe’ connects ‘mixing tank’ with the ‘digester’.

Working of Deenbandhu Biogas Plant:

Cattle dung slurry prepared in 1 : 1 ratio with water is fed upto the level of second step in the outlet tank. As the gas generates and accumulates in the empty portion of the plant, it presses the slurry of the digester and displaces it into the outlet ‘displacement chamber’. The slurry level in the digester falls whereas in the outlet chamber it starts rising. This fall and rise continues till the level in the digester reaches the upper end of the outlet opening and at this stage the slurry level in the outer tank reaches the height of discharge opening.

Advantages of Deenbandhu Biogas Plant:

1. This plant requires less space being mainly underground.

2. Its cost is reduced as the surface area is minimised by joining segments of two different diameter spheres at their bases.

3. It is 30 per cent economical as compared to Janata biogas plant.

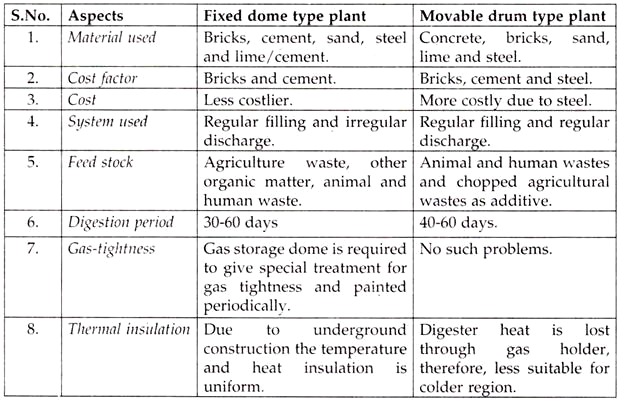

Comparison between Fixed Dome Type and Movable Drum Type Biogas Plants:

The comparison between fixed dome type and movable drum type biogas plants is given below: