Are you looking for an essay on ‘Biogas’? Find paragraphs, long and short essays on ‘Biogas’ especially written for school and college students.

Essay on Biogas

Essay Contents:

- Essay on the Introduction to Biogas

- Essay on Anaerobic Digestion System (Biogas Technology)

- Essay on the Factors Affecting Generation of Biogas

- Essay on Biogas Plants

- Essay on the Methods of Maintaining Biogas Production

- Essay on the Community Night-Soil Based Biogas Plant

- Essay on the Guidelines for Fixing Optimum Size of a Biogas Plant

- Essay on the Site Selection of a Biogas Plant

- Essay on the Problems Related to Biogas Plants in India

- Essay on the Fuel Properties of Biogas

- Essay on the Types of Liquid Waste Used in Biogas

- Essay on the Advantages of Biogas Production

- Essay on the Applications of Biogas

Essay # 1. Introduction to Biogas:

The main source for biogas is wet cattle dung.

Some of the other sources are:

(i) Sewage

(ii) Crop residue

(iii) Vegetable wastes

(iv) Water hyacinth

(v) Alga

(vi) Poultry droppings

(vii) Pig-manure

(viii) Ocean kelp

i. Biomass, a mixture containing 55-65% methane, 30-40% carbon dioxide and the rest being the impurities (hydrogen, hydrogen sulphide and some nitrogen), can be produced from the decomposition of animal, plant and human waste.

ii. It is a clean but slow-burning gas and usually has a heating value about 18 kJ/m3.

iii. It can be used directly in cooking, reducing the demand for firewood.

iv. The material from which the biogas is produced retains its value as fertilizer and can be returned to soil.

v. ‘Biogas’ is produced by digestion, pyrolysis or hydrogasification. Digestion is a biological process that occurs in the absence of oxygen and in the presence of anaerobic organisms at ambient pressures and temperatures of 35-70°C. The container in which this digestion takes place is known as the digester.

Essay # 2. Anaerobic Digestion System (Biogas Technology):

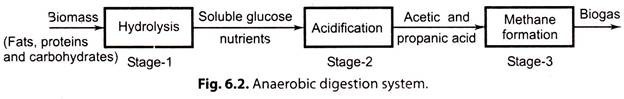

Anaerobic digestion system consists of the following three stages:

1. Hydrolysis (Stage-1)

2. Acidification (Stage-2)

3. Methane formation (Stage-3).

These stages are shown in the Fig. 6.2 shown below:

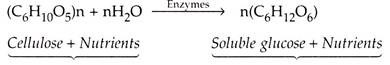

1. Hydrolysis (Stage 1):

In this stage, the complex compounds, such as fats, proteins and carbohydrates are broken into small size compounds through the effluence of water and enzymes called “Hydrolysis”.

Reaction of Hydrolysis:

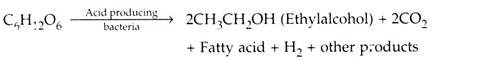

2. Acidification (Stage 2):

In this stage, the soluble glucose and nutrients are converted into simpler volatile fatty acid and acetic acid as byproduct, that accounts for 70 per cent of methane byproducts with the help of acid forming bacteria.

Reaction of Acidification:

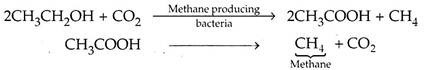

3. Methane Formation (Stage 3):

During this stage, the methane producing bacteria converts the organic acid into biogas having its main constituent as “methane”.

Reactions of Methane Formation:

Advantages of Anaerobic Digestion:

Anaerobic digestion claims the following advantages:

1. The biogas produced as a byproduct, has a calorific value (which can be used as energy source for producing steam or hot water).

2. Low nutrient requirement.

3. Low odour.

4. Reduction of pathogens.

5. Stable sludge.

6. New sludge production.

7. Sludge acts as a soil conditioner.

8. Low running cost.

Essay # 3. Factors Affecting Generation of Biogas:

The generation of biogas is affected by the following factors:

1. Temperature,

2. Loading rate,

3. Solid concentration,

4. pH value,

5. Retention period,

6. Nutrients concentration, and

7. Toxic substances.

1. Temperature:

The anaerobic fermentation process is temperature dependent. The process of the digestion and gasification proceeds at the highest rate when the temperature lies between 35°C – 38°C. The process becomes slow within temperature range of 45°C-45°C and then rises to a peak between 55°C-60°C. Thus, the rate of gas production ‘increases’ with the increase in temperature but the percentage of methane ‘decreases’.

2. Loading Rate:

“Loading rating” is the weight of volatile solids fed to a digester per day. It depends upon the plant capacity and also the retention period. Thus, for a given capacity of the digester, if the loading rate is increased the ‘retention period’ is correspondingly decreased.

3. Solid Concentration:

Normally, 7 to 9 parts of solid in 100 parts of the slurry is considered ideal.

It is recommended that 4 parts of the cattle dung to be mixed with 5 parts of water.

4. pH Value:

pH denotes the acidity and alkalinity of the substrate. The pH less than 7 is called ‘acidic’ and pH more than 7 is called ‘alkaline’ and pH solution of 7 is called ‘neutral’.

5. Retention Period:

It is the time period for which fermentable material resides inside the digester. This period ranges from 30 days to 50 days depending upon the climatic conditions.

Generally it is observed that maximum gas production takes place within ‘first four weeks’ and it tapers off gradually.

6. Nutrients Concentration:

The major nutrients required by the bacteria in the digester are C, H2, O2, N2, P and S. To maintain proper balance of nutrients an extra raw material, rich in P and N2, should be added along with cattle dung to obtain maximum gas production.

7. Toxic Substance:

The presence of ammonia, pesticides, detergents and heavy metals are considered as toxic substances to micro-organisms, since their presence reduces fermentation rate.

Essay # 4. Biogas Plants:

Introduction to Biogas Plants:

Biogas plants converts’ wet biomass into biogas (methane) by the process of “anaerobic fermentation”.

The bacteria called “anaerobe” carrier out digestion of biomass without oxygen and produces methane (CH4) and carbon dioxide (CO2).

Biogas plants are very popular in India particularly in rural areas.

Raw Materials Used in Biogas Plant:

1. Animal wastes- Cattle dung, urine, fish wastes, piggery wastes etc.

2. Human wastes- Waste matter, urine etc.

3. Agriculture wastes- Sugarcane trash, tobacco waste, oil cake, vegetable wastes etc.

4. Industrial wastes- Sugar factory, paper factory etc.

Main Components of a Biogas Plant:

The main components of a biogas plant are enumerated and briefly described below:

a. Digester;

b. Gas holder;

c. Inlet;

d. Outlet;

e. Slurry mixing tank;

f. Gas outlet pipe;

g. Stirrer.

a. Digester:

A digester is also called “fermentation tank” and is mostly embedded partly or fully in the ground. It is generally cylindrical in shape and is made of bricks. It holds the slurry for a sufficiently long time to complete the digestion.

b. Gas Holder:

Its function is to keep the gas for subsequent use. The gas connection for use is taken from the top of the gas holder. In some designs of biogas plants, it may be separable from the digester whereas in other designs it may be an integral part of the digester.

c. Inlet:

An inlet is provided to add the mixture of dung and water to the digester, and is sloped accordingly.

d. Outlet:

The provision of an outlet is made to take out the digested portion of slurry.

e. Slurry Mixing Tank:

This tank carries out mixing of the dung with water for induction in the digester, through the inlet.

f. Gas Outlet Pipe:

It is used for taking out gas from the gas holder and is connected to its top. The other end of the pipe is connected with the device using biogas.

g. Stirrer:

The stirrers are provided in biogas plants of large size for stirring the slurry for fermentation inside the fermentation chamber to ensure the normal production of gas.

The small size biogas plants can function without a stirring device.

Some biogas plants also have the arrangement of external heating by solar / electrical energy etc. under colder climates.

The biogas plants are built in several sizes, small (0.5 m3/day) to very large (2500 m3/day). Accordingly, the configurations are simpler to complex.

Essay # 5. Methods of Maintaining Biogas Production:

Following techniques are suggested for maintaining the biogas production:

1. Insulating the gas plant.

2. Compositing.

3. Hot water circulation.

4. Use of chemicals.

5. Solar energy systems.

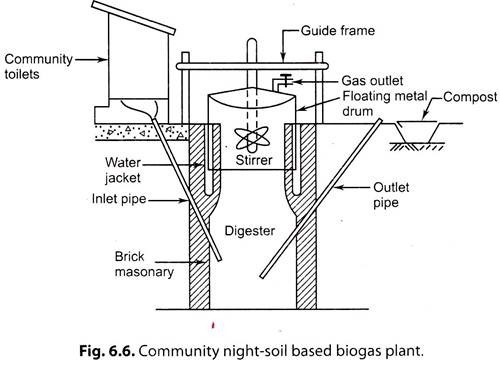

Essay # 6. Community Night-Soil Based Biogas Plant:

Such plants have been developed to facilitate sanitary treatment of human waste at community and institutional level.

Fig. 6.6 shows the cross-section of a community night-soil based biogas plant. It consists of a ‘floating metal drum’ with a ‘water jacket’. It is linked with community toilets. It can serve a population of 1000 persons, and can provide fuel for cooking, operating duel- fuel engines for water supply and generate electric power.

Essay # 7. Guidelines for Fixing Optimum Size of a Biogas Plant:

The following guidelines may be used to fix optimum size of biogas plant:

1. Type of waste.

2. Daily rate of waste to be digested.

3. Digestion period.

4. Method of stirring, if any.

5. Arrangement for raw waste feeding and discharge of digested slurry.

6. Climatic conditions.

7. Mix of raw waste.

8. Water table and sub-soil conditions.

9. Type of dome.

Essay # 8. Site Selection of a Biogas Plant:

While selecting a site for a biogas plant, the following factors must be considered:

a. Less Distance:

In order to achieve economy in pumping of gas, the distance between the plant and site of gas consumption should be less. The optimum distance for a plant of 2 m3 capacity is 10 metres.

A minimum gradient of 1 percent must be made available for the line to convey the gas.

b. Open Space:

For gas generation at adequate rate, there should an open space sufficient enough for the sunlight to fall on the plant to provide essential temperature between 15 to 30°C.

c. Space Requirements:

To carry out day-to-day operation and maintenance, sufficient space must be available. As a guideline 10 to 12 m2 area is required per m3 of the gas.

d. Availability of Water:

Availability of plenty of water must be ensured, to prepare proper cattle dung slurry for gas generation.

e. Water Table:

As the biogas plant is normally constructed underground, care should be taken to prevent seepage of water. In case the water table is less than 3 metres, the plant should not be constructed.

f. Transportation Cost of Cattle Dung/Materials:

To reduce the transportation cost of cattle dung/materials for biogas generation, the distance between the materials and site of the biogas plant should be minimum.

g. Distance from Wells:

A biogas plant should be constructed at a minimum distance of 15 metres to check the seepage of fermented slurry which may pollute the water of well.

h. Seasonal Run-Off:

To prevent the interference of run-off water during monsoon, intercepting ditches or bunds may be constructed.

Essay # 9. Problems Related to Biogas Plants in India:

Reasons why biogas plants are not much successful in India, even after the subsidies provided by Government of India (or problems related to biogas plants) are as follows:

1. Gas forming methanogenic bacteria are very sensitive towards temperature. During winter the temperature falls and there is decrease in activity of the bacteria and the gas production rate reduces.

2. A lot of problem arises due to lack of training to the biogas plant owners for the operation of plant.

3. Collecting dung, mixing with water and draining out the waste is tiresome and time consuming process.

4. Some persons add urea-fertilizer (to augment gas production) in large quantities due to which toxicity of ammonia, nitrogen may cause a decrease in gas production.

5. The cleaning and recharging of whole tank of biogas plant is necessary after 3 or 4 years, which is not so easy.

6. Handling of effluent slurry is major problem. For domestic plant, 200 litres capacity oil drums can be used to carry this effluent; this will require some human labour.

7. In some areas like Himachal, Jammu and Kashmir the average annual temperature is low which is not adequate for anaerobic digestion.

Essay # 10. Fuel Properties of Biogas:

The important properties of biogas, generated by anaerobic fermentation of organic wastes are as follows:

Composition – Percentage by Volume:

Methane = 50-60; Carbon dioxide = 30-45; Hydrogen = 5-10;

Nitrogen = 0.5-0.7; Hydrogen sulphide and oxygen = Traces.

Calorific Value:

60% methane : 22.35 to 24.22 MJ/m3

without CO2: 33.52 to 35.39 MJ/m3

Octane rating:

Without CO2: 130

With CO2: 110

Ignition temperature: 650°C

Air-to-methane ratio for complete

Combustion (by volume): 10 to 1

Explosive limits to air (by volume): 5 to 15

The main products of the biogas plant are ‘fuel gas’ and ‘organic manure’. Biogas is a flammable gas. ‘Methane’ is the only combustible portion in the gas and hence around 60% by volume only is usable for combustion.’

Essay # 11. Types of Liquid Waste Used in Biogas:

Liquid waste may be of following types:

1. Sewage;

2. Distillary waste;

3. Pulp and paper mill black liquor waste.

1. Sewage:

Anaerobic digestion is used to produce gas for extracting energy from sewage. Anjana sewage treatment plant (at Surat) has three sludge digesters with a total capacity of 82.5 million litres per day; each digester generates about 2500 m3 biogas daily. A scrubber system is employed to clean the gas, to make it suitable for use in a 100 percent biogas engine to generate electricity.

2. Distillary Waste:

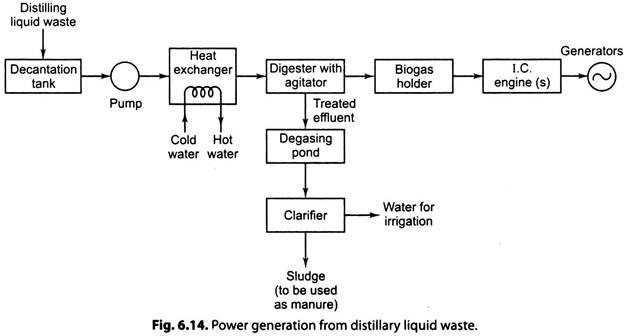

Fig. 6.14 shows a schematic diagram of power generation from distillary liquid waste (carrying rich raw material for producing gas).

i. Distillary liquid waste is collected in a ‘decantation tank’ where the suspended solids settle down. Decanted liquid/effluent containing fermented molasses is pumped into a ‘digester’ through a ‘heat exchanger’, where it (effluent) is cooled to maintain the digester temperature at 36-38°C.

ii. Effluent is than allowed to be digested anaerobically for about 12-15 days, during which gas is produced. The biogas accumulates in a biogas holder and is stored under pressure using a pressure control device. The gas is used to run the I.C. engine(s) which in turn generate electrical power through generator(s).

3. Pulp and Paper Mill Black Liquor Waste:

A large amount of energy and water is consumed by the pulp and paper industry. The waste discharge water contains compounds of wood and raw material which are useful for recovery of energy. A plant for biomethanation of bagasse wash effluent is installed at Karur (in Tamil Nadu), based on USAB technology.

Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD) removal is 94% and 89% respectively, with gas production of 0.37 m3/kg. At present, about 1500 m3 of gas is generated per day, which is used in a lime-mud reburning kiln. The gas output from the plant meets 50% heat load of the kiln, equivalent to about 12.5 x 103 litres of furnace oil.

Essay # 12. Advantages of Biogas Production:

1. Gas production is cheap.

2. Less pollution.

3. Waste material can be used as fertilizer.

4. Gas is used for cooking, lighting, as fuel etc.

Essay # 13. Applications of Biogas:

Biogas is a flammable fuel gas usually with 60% CH4 and rest CO2. The gas can be upgraded by removal of CO2 with water scrubbing and the gas with high heating value can be used in I.C. engine.

The main applications of biogas are:

(i) Cooking.

(ii) Domestic lighting and heating.

(iii) I.C. engines.

(iv) Fuel cells-electricity can be produced by using biogas in a fuel cell with air as oxidant. The electrolyte is usually potassium hydroxide (KOH).

Application of Biogas in Petrol Engines:

i. Biogas can be used in petrol engines after initial starting of the engine on petrol. It needs about 550 litres of gas per kWh to run a petrol engine.

ii. Engine can also run as duel fuel engine either on biogas or petrol It has the advantage that the engine can run on petrol if the biogas is not available or vice- versa.

Application of Biogas in “Diesel Engines”:

i. Biogas can be better used in diesel engines (as a duel fuel engine).

ii. It is more convenient to use biogas since it has high self-ignition temperature of about 730°C.

Advantages of Using Biogas in Engines:

1. It has ample flexibility of operation.

2. A uniform gas-air mixture is available in multi-cylinder engines.

3. Clean combustion reduces the wear of engine parts.

4. Lubricating oil consumption is reduced.

5. Emissions of CO are greatly reduced.

6. NOx emissions are also reduced.