Are you looking for an essay on ‘Nuclear Reactors’? Find paragraphs, long and short essays on ‘Nuclear Reactors’ especially written for school and college students.

Essay on Nuclear Reactors

Essay Contents:

- Essay on the Definition of Nuclear Reactors

- Essay on the Classification of Nuclear Reactors

- Essay on the Essential Components of a Nuclear Reactor

- Essay on the Power of a Nuclear Reactor

- Essay on Some Important Nuclear Reactors

Essay # 1. Definition of Nuclear Reactors:

A nuclear reactor is an apparatus in which nuclear fission is produced in the form of a controlled self-sustaining chain reaction. In other words, it is a controlled chain- reacting system supplying nuclear energy. It may be looked upon as a sort of nuclear furnace which burns fuels like U235, U233 or Pu239 and, in turn, produces many useful products like heat, neutrons and radioisotopes.

Mechanism of Heat Production:

Most of the energy is imparted to the two fission fragments into which the nucleus divides causing them to move at high speed. However, because they have taken birth in a dense mass of metal, they are rapidly slowed down and brought to rest by colliding with other atoms of the metal.

In so doing, their energy is converted into heat in much the same way as energy given up by a slowing motor can be converted into heat in the brake lining. In this way, the mass of uranium metal gets heated up.

Essay # 2. Classification of Nuclear Reactors:

Nuclear reactors are “classified” according to the chain reacting system, use, coolants, fuel material etc.

A. Neutron Energies at which the Fission Occurs:

(i) Fast fission is caused by high energy neutrons Fast reactors

(ii) Intermediate or epithermal Intermediate reactors

(iii) Low energy i.e., thermal Slow reactors.

On the basis of the energy of the neutrons to cause fission the reactors have been divided into three groups—fast, intermediate and thermal.

(a) In “Fast reactors” the high velocity neutrons produced by fission are utilised directly to cause fission of the fuel in the reactor. The velocity of the neutrons is not reduced deliberately.

(b) If in a reactor the fission process is maintained due to the slow neutrons capture, the reactor is known as “Slow reactor”. The minimum velocity to which neutrons are slowed down before the fission is equal to the thermal velocity which the slow neutrons may acquire in a state of thermal equilibrium with the medium.

This velocity is of the order of 2150 m/s at room temperature which is equivalent to 1/40 or neutron energy. The neutrons associated with the energy of this order are known as thermal neutrons and the reactor as “Thermal reactors”. With the moderator the neutrons are slowed down. The main advantage is that the probability of reaction increases.

(c) If the velocity of neutrons is kept between both the above noted limits, the reactors are termed as “Intermediate reactors”.

B. Fuel-Moderator Assembly:

(i) Homogeneous reactors;

(ii) Heterogeneous reactors.

In “Hemogeneous reactor” the fuel and moderator are mixed to form a homogeneous material, i.e., uranium fuel salt forms a homogeneous solution in water which is a moderator, or fine particles of uranium and carbon give a mechanical mixture.

In “Heterogeneous reactor” the fuel is used in the form of rods, plates or wires etc. and the moderator surrounds the each fuel element in the reactor core.

C. Fuel State:

(i) Solid

(ii) Liquid

(iii) Gas

The nuclear fuel is available in three states—solid, liquid and gas. In reactors the fuel is mostly used in solid state or in the form of solution dissolved in water. The “liquid metal reactors” are in practical use.

D. Fuel Material:

(i) Natural uranium with U235 contents (occurs in nature)

(ii) Enriched uranium with more than 0.71 of U235

(iii) Pu239, Pu241 or Pu239 (man made)

(iv) U233 (man made).

Considering the necessary requirement of fission process and its availability economically the fuels used in reactors are uranium, plutonium and thorium. U235 is easily available in natural uranium (i.e., 0.7%) and its content increases upto 90% in enriched uranium.

E. Moderator:

(i) Water

(ii) Heavy water (D20)

(iii) Graphite

(iv) Beryllium or beryllium oxide

(v) Hydrocarbons or hydrides.

A moderator’s function is to absorb the part of the kinetic energy of the neutrons. The neutrons collide directly with the moderator and thus slowed down. No ideal moderator is available in nature or has been produced artificially. The light weight nuclei materials are not suited at all as a moderator because they do not possess the property of absorption of neutrons.

Light water, heavy water and graphite are the most common moderators used in reactors.

F. Principal Product:

(i) Research Reactors:

These are designed to produce the high neutron flux for research work and these neutrons are used to determine the neutron properties of interaction with the nuclei and the effect of bombardment of neutrons on the materials.

The reactors are operated at high neutron flux and low power level otherwise the cooling will be a problem. The unit is cooled constantly during operation. The by-products are heat and fission products which are removed during operation.

(ii) Power Reactors:

In these reactors the energy is produced in heat form which is carried away to the heat exchanger by circulating the coolant through the reactor and heat exchanger. In the heat exchanger the coolant converts the water into steam to run the turbine. The by-products are fission products, neutrons and other radiation particles.

These reactors are useful to produce huge amount of power and are widely used in power plant stations. In such reactors consumption is very low.

(iii) Breeder Reactors:

A breeder reactor converts fertile materials into fissionable materials such as U238 and Th232 to Pu239 and U233 respectively besides the power production. It is worth noting that the amount of fissionable material produced is more than its consumption of fissionable material. By-products are the same as those of power reactors.

(iv) Production Reactors:

The output of such reactors is radioactive materials which are used as sources of radiation and tracers in research in all areas of science. By-products are the same as those of power reactors.

G. Coolant:

(i) Air, carbon or helium-cooled reactors

(ii) Water or other liquid-cooled reactors

(iii) Liquid metal-cooled reactors.

In gas-cooled reactors the amount of gas required to extract the heat is too much and therefore these reactors are expensive. Gases have poor heat carrying capacity. CO2 and He have been used in the early reactors. Mostly water is used as a coolant.

Liquid metal cooled reactors are also suitable as the metal is having high boiled point, and low steam pressure. These are the power reactors.

H. Construction of Core:

(i) Cubical

(ii) Cylindrical

(iii) Octagonal

(iv) Spherical

(v) Slab

(vi) Annulus.

The proper shape to the core is given on the practical consideration and can have cubical, cylindrical or ring type construction.

Essay # 3. Essential Components of a Nuclear Reactor:

The essential components of a nuclear reactor are as follows:

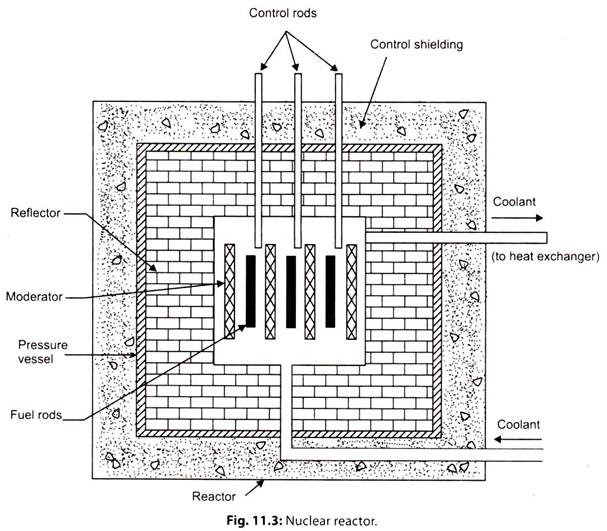

A. Reactor Core: Refer to Fig. 11.3.

The reactor core is that part of a nuclear power plant where fission chain reaction is made to occur and where fission energy is liberated in the form of heat for operating power conversion equipment. The core of the reactor consists of an assemblage of fuel elements, control rods, coolant and moderator. Reactor cores generally have a shape approximating to a right circular cylinder with diameters ranging from 0.5 m to 15 m.

The pressure vessels which houses the reactor core is also considered a part of the core (Fig. 11.3). The fuel elements are made of plates or rods of uranium metal. These plates or rods are usually clad in a thin sheath of stainless steel, zirconium or aluminium to provide corrosion resistance, retention of radioactivity and in some cases, structural support. Enough space is provided between individual plates or rods to allow free passage of the coolant.

B. Reflector:

A reflector is usually placed round the core to reflect back some of the neutrons that leak out from the surface of the core. It is generally made of the same materials as the moderator.

C. Control Mechanism:

It is an essential part of a reactor and serves the following purposes:

(i) For starting the reactor i.e., to bring the reactor up to its normal operating level.

(ii) For maintaining at that level i.e., keep power production at a steady state.

(iii) For shutting the reactor down under normal or emergency conditions.

The control system is also necessary to prevent the chain reaction from becoming violent and consequently damaging the reactor. The effective multiplication factor of the reactor is always kept greater than unity in order that the number of neutrons keeps on increasing in successive generations.

As the number of neutrons and hence the neutron flux density increases, the temperature also increases. Unless the growth is checked at some point, the reactor is likely to be damaged as a result of too rapid liberation of energy.

Note:

The control system works on the simple principle of absorbing the excess neutrons with the help of control rods either made of boron steel or cadmium strips. Both these materials have very large cross-section for thermal neutrons i.e., they are very good absorbers of slow neutrons and also have the advantage of not becoming radioactive due to neutron capture. By pushing these rods deeper into the central core, any amount of excess neutrons can be absorbed.

Once the reactor has reached pre-determined power level, these control rods serve to keep the value of K = 1 so that there is no further increase in the number of neutrons from one generation to another. If, at some stage, it is desired to increase the neutron flux density and hence the power level, the rods are partially pulled out thereby allowing K to exceed unity.

For shutting down the reactor, the control rods are inserted to a considerable depth so that K becomes less than unity and the chain-reaction can no longer be maintained. To start up the reactor, all that is necessary is to carefully withdraw the control rods and then adjust them till required output level is attained. Movement of control rods can be manual or made automatic with the help of carefully designed servomechanism.

D. Moderator:

In a nuclear reactor the function of a moderator is:

(i) To slow down the neutrons from the high velocities and hence high energy level, which they have on being released from the fission process. Neutrons are slowed down most effectively in scattering collisions with nuclei of the light elements, such as hydrogen, graphite, beryllium etc.

(ii) To slow down the neutrons but not absorb them.

The desirable properties of a moderator in a reactor are:

1. High slowing down power.

2. Low parasite capture.

3. Non-corrosiveness (or corrosiveness resistance).

4. Machinability (if solid).

5. High melting point for solids and low melting point for liquids.

6. Chemical and radiation stability.

7. High thermal conductivity.

8. Abundance in pure form.

H2O, D2O (heavy water), He (gas), Be and C (graphite) are the commonly used moderators.

As a moderator D2O is the best material available (moderating ratio of D2O is 12000 as compared to 72 for H2O and 170 for carbon) because:

(i) It has excellent neutron slowing properties,

(ii) It has very small cross-section for neutron capture, and

(iii) It can be used as a coolant as well.

Its disadvantages are:

(i) It has low boiling point so that it necessitates pressurisation, and

(ii) It is very expensive.

But, the advantages of D2O as moderator or moderator coolant outweigh its high cost.

E. Coolants:

The function of a coolant is to remove the intense heat produced in the reactor and to bring out for being utilised.

The desirable characteristics for a reactor coolant are:

1. Low parasite capture.

2. Low melting point.

3. High boiling point.

4. Chemical and radiation stability.

5. Low viscosity.

6. Non-toxicity.

7. Non-corrosiveness.

8. Minimum induced activity (short half-lives, low energy emission).

9. High specific heat (reduces pumping power and thermal stresses).

10. High density (reduces pumping power and physical plant size).

Commonly Used Coolants:

Santiwax R (organic, Hg, He, CO2).

The most widely-used gaseous coolant is CO2 particularly in large-power reactors. It is:

(i) Cheap,

(ii) Does not attack metals at reasonable temperatures, and

(iii) Has small cross-section for neutron capture.

F. Measuring Instruments:

Main instrument required is for the purpose of measuring thermal neutron flux which determines the power developed by the reactor.

G. Shielding:

Shielding is necessary in order to:

(i) Protect the walls of the reactor vessel from radiation damage, and also to

(ii) Protect operating personnel from exposure to radiation.

The first known as thermal shield is provided through the steel lining, while the other called external or biological shield is generally made of thick concrete surrounding the reactor installation.

Among the nuclear radiations produced in a reactor the alpha and beta particles, thermal (slow) neutrons, fast neutrons and gamma rays are harmful ones and must be shielded against. Of these only the fast neutrons and gamma rays present some serious difficulty in designing the reactor shielding, since alpha and beta particles can be stopped by a fraction of an inch of a solid substance, while thermal neutrons can be automatically guarded against with a shield thick enough to provide protection against fast neutrons and gamma rays.

The effectiveness of a nuclear shield against gamma rays approximately depends upon its mass. A heavy material like lead will be a more effective shield per unit weight, than a light element such as carbon. On the other hand, light elements, particularly hydrogen are much more effective per unit weight than heavy elements for fast neutron shielding.

Concrete is a material that offers a compromise between these two extreme characteristics of shielding material for both gamma rays and fast neutrons. It is a material which has low cost and is easily available.

The actual design of the shield, however, involves the following considerations:

(i) The total amount of radiation produced in the reactor.

(ii) The amount of radiation that can be permitted to leak through the shield.

(iii) The shielding properties of material.

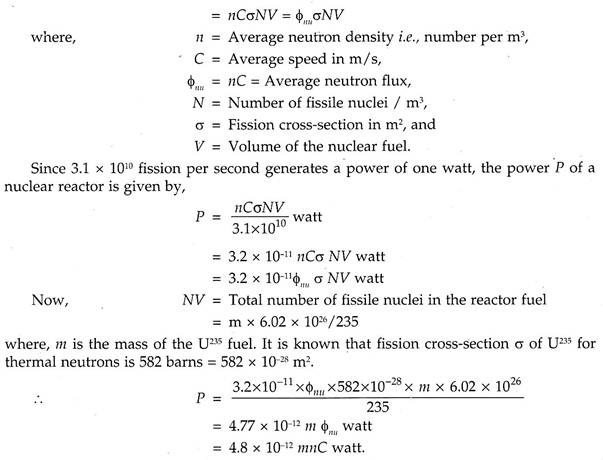

Essay # 4. Power of a Nuclear Reactor:

The fission rate of a reactor, i.e., total number of nuclei undergoing fission per second in a reactor is

Essay # 5. Some Important Nuclear Reactors:

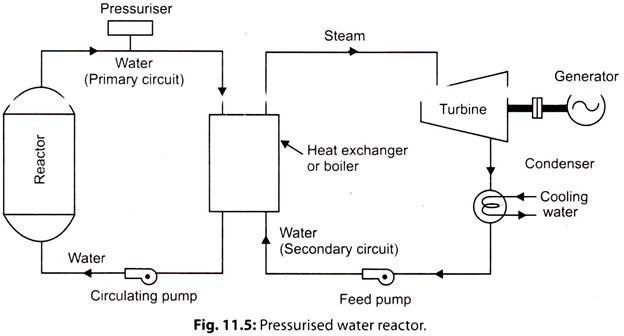

1. Pressurised Water Reactor (PWR):

A pressurised water reactor, in its simplest form, is a light water-cooled and moderated thermal reactor having an unusual core design, using both natural and highly enriched fuel.

The principal parts of the reactor are:

1. Pressure vessel

2. Reactor thermal shield

3. Fuel elements

4. Control rods

5. Reactor containment

6. Reactor pressuriser.

The components of the secondary system of pressurised water plant are similar to those in a normal steam station.

Refer to Fig. 11.5. In PWR, there are two circuits of water, one primary circuit which passes through the fuel core and is radioactive. This primary circuit then produces steam in a secondary circuit which consists of heat exchanger or the boiler and the turbine. As such the steam in the turbine is not radioactive and need not be shielded. The pressure in the primary circuit should be high so that the boiling of water takes place at, high pressure.

A pressuring tank keeps the water at about 100 kgf/cm2 so that it will not boil. Electric heating coils in the pressuriser boil some of the water to form steam that collects in the dome. As more steam is forced into the dome by boiling, its pressure rises and pressurises the entire circuit. The pressure may be reduced by providing cooling coils or spraying water on the steam.

Water acts both as coolant as well as moderator. Either heavy water or the light water may be used for the above purpose.

A pressurised water reactor can produce only saturated steam. By providing a separate furnace, the steam formed from the reactor could be superheated.

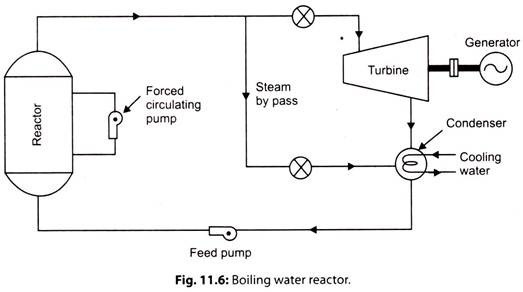

2. Boiling Water Reactor (BWR):

In a boiling water reactor enriched fuel is used. As compared to PWR, the arrangement of BWR plant is simple. The plant can be safely operated using natural convection within the core or forced circulation as shown in the Fig. 11.6. For the safe operation of the reactor the pressure in the forced circulation must be maintained constant irrespective of the load. In case of part load operation of the turbine some steam is by-passed.

3. CANDU (Canadian-Deuterium-Uranium) Reactor:

CANDU is a thermal nuclear power reactor in which heavy water (99.8% deuterium oxide D2O) is the moderator and coolant, as well as the neutron reflector. This reactor was developed in Canada and is being extensively used in this company. A few CANDU reactors are operating or under construction in some other countries as well.

In this type of reactor the natural uranium (0.7% U235) is used as fuel and heavy water as moderator. These reactors are more economical to those countries which do not produce enriched uranium, as the enrichment of uranium is very costly.

CANDU (heavy water) reactor, differs basically from light-water reactors (LWRS) in that in the latter the same water serves as both moderator and coolant, whereas in the CANDU reactor the moderator and coolant are kept separate. Consequently unlike the pressure vessel of a LWR, the CANDU reactor vessel, which contains the relatively cool heavy water moderator, does not have to withstand a high pressure. Only the heavy water coolant circuit has to be pressurised to inhibit boiling in the reactor core.

4. Gas-Cooled Reactor:

In such a type of reactor, the coolant used can be air, hydrogen, helium or carbondioxide. Generally inert gases are used such as helium and carbondioxide. The moderator used is graphite. The problem of corrosion is reduced much in such reactors. This type of reactor is more safe specially in case of accidents and the failure of circulating pumps. The thickness of gas cooled reactor shield is much reduced as compared to the other types of reactors.

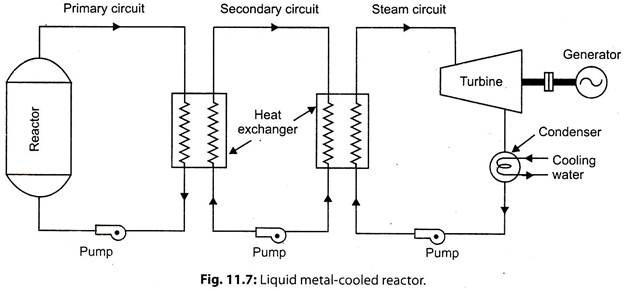

5. Liquid Metal-Cooled Reactors:

Sodium-graphite reactor (SGR) is one of the typical liquid metal reactors. In this reactor sodium works as a coolant and graphite works as moderator.

Sodium boils at 880°C under atmospheric pressure and freezes at 95°C. Hence sodium is first melted by electric heating system and is pressurised to about 7 bar. The liquid sodium is then circulated by the circulation pump.

The reactor will have two coolant circuits or loops:

(i) The primary circuit has liquid sodium which circulates through the fuel core and gets heated by the fissioning of the fuel. This liquid sodium gets cooled in the intermediate heat exchanger and goes back to the reactor vessel.

(ii) The secondary circuit has an alloy of sodium and potassium in liquid form. This coolant takes heat from the intermediate heat exchanger which gets heat from liquid sodium of primary circuit. The liquid sodium-potassium then passes through a boiler which is once through type having tubes only.

The steam generated from this boiler will be superheated. Feed water from the condenser enters the boiler, the heated sodium-potassium passing through the tubes gives it heat to the water thus converting it into steam. The sodium-potassium liquid in the second circuit is then pumped back to the intermediate heat exchanger thus making it a closed circuit.

The reactor vessel, primary loop and the intermediate heat exchanger are to be shielded for radio-activity. The liquid metal be handled under the cover of an inert gas, such as helium, to prevent contact with air while charging or draining the primary or secondary circuit/loop.

The arrangement of a sodium-graphite reactor (SGR) is shown in Fig. 11.7.

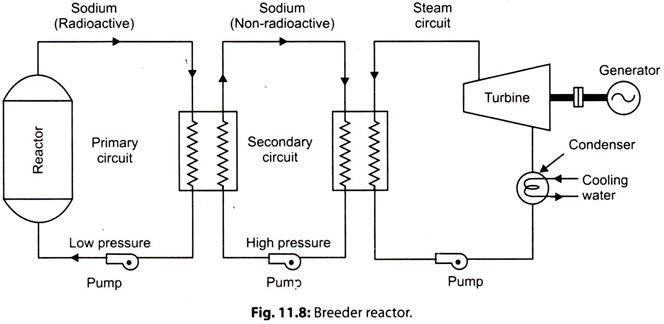

6. Breeder Reactor:

In its simplest form a fast breeder reactor is a small vessel in which necessary amount of enriched plutonium is kept without using moderator. A fissible material, which absorbs neutrons, surrounds the vessels. The reactor core is cooled by liquid metal.

Necessary neutron shielding is provided by the use of light water, oil or graphite. Additional shielding is also provided for gamma rays. (It is worth noting that when U235 is fissioned, it produces heat and additional neutrons. If some U238 is kept in the same reactor, part of the additional neutrons available, after reaction with U235, convert U238 into fissible plutonium).

Fig. 11.8 shows a schematic diagram of a breeder reactor.