Here s an essay on ‘Solid Waste Management’ for class 8, 9, 10, 11 and 12. Find paragraphs, long and short essays on ‘Solid Waste Management’ especially written for school and college students.

Essay on Solid Waste Management

Essay # 1. Introduction to Solid Waste Management:

Waste management is the collection, transport, processing, recycling or disposal, and monitoring of waste materials. The term usually relates to materials produced by human activity, and is generally undertaken to reduce their effect on health, the environment or aesthetics. Waste management is also carried out to recover resources from it. Waste management can involve solid, liquid, gaseous or radioactive substances, with different methods and fields of expertise for each.

Waste management practices differ for developed and developing nations, for urban and rural areas, and for residential and industrial producers. Management for non-hazardous residential and institutional waste in metropolitan areas is usually the responsibility of local government authorities, while management for non-hazardous commercial and industrial waste is usually the responsibility of the generator.

Essay # 2. Waste Management Concepts:

There are a number of concepts about waste management which vary in their usage between countries or regions.

Some of the most general, widely-used concepts include:

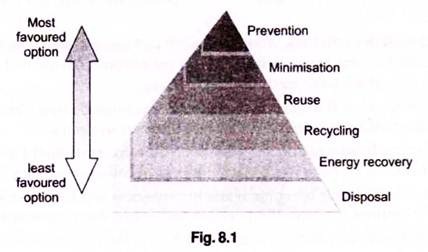

i. Waste hierarchy:

The waste hierarchy refers to the “3 Rs” reduce, reuse and recycle, which classify waste management strategies according to their desirability in terms of waste minimization. The waste hierarchy remains the cornerstone of most waste minimization strategies. The aim of the waste hierarchy is to extract the maximum practical benefits from products and to generate the minimum amount of waste.

ii. Extended producer responsibility:

Extended Producer Responsibility (EPR) is a strategy designed to promote the integration of all costs associated with products throughout their life cycle (including end of life disposal costs) into the market price of the product. Extended producer responsibility is meant to impose accountability over the entire lifecycle of products and packaging introduced to the market. This means that firms which manufacture, import and/or sell products are required to be responsible for the products after their useful life as well as during manufacture.

iii. Polluter pays principle:

The Polluter Pays Principle is a principle where the polluting party pays for the impact caused to the environment. With respect to waste management, this generally refers to the requirement for a waste generator to pay for appropriate disposal of the waste.

Essay # 3. Steps for Solid Waste Management (Collection, Conveyance and Disposal):

Solid waste can be disposed to land or oceans. Solid wastes can also be recovered and reprocessed, a procedure popularly known as recycling. Before disposal or recovery, however, the waste must be collected. All these i.e., collection, disposal and/or recovery form a part of the solid waste management system.

A. Collection:

i. Access to waste collection points:

Many sources of waste might only be reached by roads or alleys which may be inaccessible to certain methods of transport because of their width, slope, congestion of surface.

ii. Public awareness and attitudes to waste:

This can affect the readiness to carry waste to a shared container, the willingness to accept the proximity of a shared container, the willingness to segregate waste to assist recycling, the frequency at which wastes should be collected, the amount of litter and animal excreta that are left on the street the willingness to pay for waste management services and the social groups from which waste management staff can be drawn.

iii. Collection includes all the activities:

Associated with gathering of solid wastes and hauling of the waste collected to the location from where collection vehicles will transport it to disposal site.

There are three basic methods of collection are:

1. Community storage point:

The municipal refuge is taken to fixed storage bins and stored till the waste collection agency collect it daily for disposal in vehicle.

2. Kerb side collection:

In advance of collection time the refuse is brought in containers and placed on the foot way, from it is collected by waste collection agency.

3. Block collection:

Individuals bring the waste in containers and hand it over to the collection staff who empties it into waiting vehicle and return the containers to individuals.

The collection truck and crew are most important members of the collection system. Collection trucks commonly used are of the enclosed, compacting type. Compaction in a collection vehicle temporarily reduces the refuse volume by about 80%. Mechanical collection systems should be used. These systems consist of standardized containers and truck mounted lifting mechanism. The crew parks its truck near the container placed in road side and lift it at the backside of the truck. By mechanical handling the container is emptied into the truck.

Modern collection systems involve pneumatic pipe line transport. In pneumatic systems, refuse is pulled by suction or vacuum through underground pipes to central underground collection site or it can go directly to the processing site.

Transportation:

The method of transport involves two steps:

(1) The transfer of waste from the smaller collection vehicle to the large transport equipment and

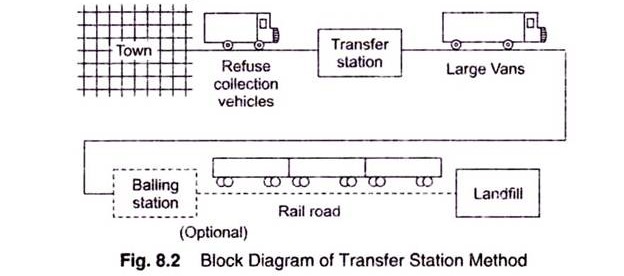

(2) The subsequent transport of the wastes, to a long distance disposal site (Fig. 8.2).

Transfer stations:

It is not always feasible for individual collection trucks to haul refuse to a waste processing plant or final disposal site when the destination is not immediate vicinity of the community in which waste is collected. Therefore, to solve this problem, there may be several transfer stations area wise where the refuse will be collected and then it will be transported to the disposal or processing sites by bigger transport vehicles.

Individual transfer station capacities may vary from less than 100 tons to more than 500 tons of wastes per day, depending upon the size of community. There are two basic modes of operation- direct discharge or storage discharge. In a storage discharge transfer station, the refuse is first emptied from the collection trucks into a storage pit or on a large platform. But in a direct discharge station, each refuse truck empties directly into the larger transport vehicle. The trailers have a capacity of 75 m3 and hold the solid waste from four collection vehicles if it is not compacted and from eight collection vehicles if it is compacted.

As an alternative to large (often international) companies that can provide most or all of the solid waste services in a city, Microenterprises or Small Enterprises (MSEs) can be involved. They often use simple equipment and labour-intensive methods, and therefore can collect waste in places where the conventional trucks of large companies cannot enter. These MSEs may be stated as a business, to create income and employment, or they may be initiated by community members who wish to improve the immediate environment of their homes.

A recurring problem with collection schemes that operate at the community level is that the community scheme generally takes the waste a relatively short distance to a transfer point, from where the waste is supposed to be collected by another organisation i.e., often municipality.

Problems of coordination and payment often result in the waste being left at transfer points for a long time. Another solution is to recycle as much of the waste locally so that there is very little need for ongoing transport to collected waste.

Waste collection methods vary widely between different countries and regions, and it would be impossible to describe them all. Many areas, especially those in less developed countries, do not have a formal waste-collection system in place.

For example, in Australia most urban domestic households have a 240-litre (63.4 U.S gallon) bin that is emptied weekly from the curb using side-or rear-loading compactor trucks. In Europe and a few other places around the world, a few communities use a proprietary collection system known as Envac, which conveys refuse via underground conduits using a vacuum system.

Roosevelt Island has had this system since 1975. In Canadian urban centres curbside collection is the most common method of disposal, whereby the city collects waste and/or recyclables and/or organics on a scheduled basis. In rural areas people usually dispose of their waste by hauling it to a transfer station. Waste collected is then transported to a regional landfill.

B. Disposal:

Waste management methods for vary widely between areas for many reasons, including type of waste material, nearby land uses, and the area available.

1. Processing of solid wastes (For volume reduction):

Processing is the second fundamental function of solid waste management. Processing improves the efficiency of solid waste disposal and prepares solid waste for subsequent recovery of materials and energy. In the not too distant past, disposal of solid wastes included open dumping, sanitary land filling and disposal at sea. Because of environmental problems associated with open dumps and sea disposal, the only acceptable method of solid waste disposal at present is sanitary land filling.

(a) Processing for recovery of materials for recycling:

Processing to segregate solid waste components may be done at the point of generation (on site processing) or at central processing facility. Onsite processing needs cooperation of waste producer; homes, commercial establishments, industries and the like. In onsite processing, wastes are segregated into types at the point of generation.

For example, paper into one container, cans into another, glass, plastic and so on. In absence of onsite processing segregation into components may be done at central facility. Unit operations, in a central facility involve screening, air classifying and magnetic separations size reduction using shredders is also used to produce a more uniformly sized products.

Screening:

Screening is a unit operation of separating a feed into oversize and under- size products. Oversize products are those that do not pass the openings of the screen, undersized products are those that do pass the opening of the screen. Solids like plastic, glass, rubber, iron scraps, tin cans, paper etc., are picked up and sent for recycling to the factories.

(b) Shredding and pulverising:

First, in the processing is the size reduction, so that total volume and weight of wastes and reduced. Volume reduction helps in utilizing less land for disposal. It also reduces cost of transportation. Alongwith volume and weight reduction, waste processing changes its form and improves its handling character. Size reduction is effected by the physical processes of shredding or pulverizing.

Shredding means cutting and tearing whereas pulverisation means crushing and grinding. Shredding and pulverising reduce the overall volume of the original or raw waste materials about 40%. This is needed, because the production of refuse derived fuel on (RDF), requires processing of the raw solid waste.

(c) Hammer mills:

One of the most common types equipment used for processing municipal solid waste (MSW) into a uniform and homogeneous mass is the hammer mill. A hammer mill is a mechanical impact device in which the waste material is cramped with a force to crush or tear individual pie of the waste. Impact is provided by several hammers that rotate at high speeds around a central horizontal or vertical shaft. It is possible to reduce the size of waste material components to uniform fragments between 25 and 50 mm with proper operation.

(d) Baling:

Compacting the solid waste into the form of rectangular blocks or bales is called baling, MSW bales are typically about 1.5 m3 in size and weight about 1 kN. Solid waste can be compacted high pressure (about-700 k Pa) in either vertical or horizontal presses, the bales are frequently wrapped with steel wire to help retain their rectangular shape during handling.

They may also be enclosed in hot a sphalt, plastic or port-land cement bags on tied with metal bands, depending on the intended use or disposal method. In this process, the volume reduction is about 90%. The basic advantage of an MSW baling process in the significant decrease in waste volume, the ease of handling the compacted refuse and the reduction of litter and nuisance potential.

(e) Incineration:

Incineration is a waste disposal method that involves the combustion of waste at high temperature. Incineration and other high temperature waste treatment systems are described as “thermal treatment”. In effect, incineration of waste materials converts the waste into heat, gaseous emissions, and residual solid ash. Other types of thermal treatment include pyrolysis and gasification.

A waste-to-energy plant (WtE) is a modern term for an incinerator that burns wastes in high-efficiency furnace/boilers to produce steam and/or electricity and incorporates modern air pollution control systems and continuous emissions monitors. This type of incinerator is sometimes called an energy-from-waste (EfW) facility.

Incineration is popular is countries such as Japan where land is a scarce resource, as incinerators do not consume as much area as a landfill. Sweden has been a leader in using the energy generated from incineration over the past 20 years. Denmark also extensively used waste-to-energy incineration in localized combined heat and power facilities supporting district heating schemes.

Incineration is carried out both on a small scale by individuals and on a large scale by industry. It is recognized as a practical method of disposing of certain hazardous waste materials (such as biological medical waste), though it remains a controversial method of waste disposal in many places due to issues such as emission of gaseous pollutants.

Breaking down complex chemical chains such a dioxin through the application of heat usually cannot be done by simply burning the material at the temperature seen in an open-air fire. It is often necessary to supplement the combustion process with gas or oil burners and air blowers to raise the temperature high enough to result in molecular breakdown.

Alternately, the exhaust gases from a natural air fire may pass through tubes heated to sufficiently high temperatures to trigger thermal breakdown. Thermal breakdown of pollutant molecules can indirectly create other pollution problems. Dioxin breakdown begins at 1000 °C, but at the same time poisonous nitrogen oxides and ozone begin to form when atmospheric nitrogen and oxygen break down at 1600 °C. This undesired oxide formation may require further catalytic treatment of the exhaust gases.

(f) Composting and anaerobic digestion:

Waste materials that are organic in nature, such as plant material, food scraps and paper products, are increasingly being recycled using biological composting and/or digestion processes to decompose the organic matter and kill pathogens. The resulting organic material is then recycled as mulch or compost for agricultural or landscaping purposes.

(g) Mechanical biological treatment:

Mechanical Biological Treatment (MBT) is a technology category for combinations of mechanical sorting and biological treatment of the organic fraction of municipal waste. MBT is also sometimes called BMT (Biological Mechanical Treatment), however this simply refers to the order of processing. The “mechanical” element is usually a bulk handling mechanical sorting state.

This removes recyclable elements from the waste (such as metals, plastics and glass), and/or processes it to produce Refuse Derived Fuel (RDF) that is burnt in power plants, boilers or kilns. The “biological” element refers to a biological digestion process, which breaks down the biodegradable component of the waste to produce biogas and/or organic- matter. The biogas can be used to generate energy; and organic matter recycled as compost.

An example of large-scale biological treatment facility is the composting facility in Edmonton, Canada, where 200,000 tonnes of residential solid waste and 22,500 tonnes of bio-solids are composted each year to produce 80,000 tonnes of compost. The co- composter itself is 38,690 square metres in size, equivalent to 8 football fields.

(h) Pyrolysis and gasification:

Pyrolysis and gasification are two related forms of thermal treatment where waste materials are heated to high temperatures with limited oxygen availability. The process typically occurs in a sealed vessel under high pressure. Converting material to energy in a sealed environment is potentially more efficient than direct incineration, with more energy able to be recovered and used.

Pyrolysis of solid waste converts the material into solid, liquid and gas products. The liquid oil and gas can be burnt to produce energy or refined into other products. The solid residue (char) can be further refined into products such as activated carbon. Gasification is used to convert organic materials directly into a synthetic gas (syngas) composed of carbon monoxide and hydrogen. The gas is then burnt to produce electricity and steam. Gasification is used in biomass power stations to produce renewable energy and heat.

C. Recovery of Resources:

Resource recovery means the obtaining of some economic benefit from material that someone has regarded as waste.

It includes:

(i) Reuse- being used for the same purpose again (such as refilling a soft drinks bottle).

(ii) Recovery-processing material so that it can be used again as the same material, such as the processing of waste paper to make pulp and then paper.

(iii) Conversion- processing the material to make something different (such as producing padding for clothing and sleeping bags from plastic bottles, or producing compost from food waste).

(iv) Energy recovery-usually referring to the burning of waste so that the heat can be used. Another method of energy recovery is to collect the gas is produced in very large sanitary landfills and use it as a fuel or to generated electricity.

Some key factors that affect the potential for resource recovery are the cost of the separated material, its purity, its quantity and its location. The costs of storage and transport are major factors that decide the economic potential for resource recovery. In many low-income countries, the fraction of material that is won for resource recovery is very high, because this work is done in a very labour- intensive way, and for very low incomes. In such situations the creation of employment is the main economic benefit of resource recovery.

A relatively recent idea is waste management has been to treat the waste material as a resource to be exploited, instead of simply a challenge to be managed and disposed of. There are a number of different methods by which resources may be extracted from waste: the materials may be extracted and recycled, or the calorific content of the waste may be converted to electricity.

The process of extracting resources or values from waste is variously referred to as secondary resource recovery, recycling, and other terms. The practice of treating waste materials as a resource is becoming more common, especially in metropolitan areas where space for new landfills is becoming scarcer. There is also a growing acknowledgment that simply disposing of waste materials is unsustainable in the long term, as there is a finite supply of most raw materials.

There are a number of methods of recovering resources from waste materials, with new technologies and methods being developed continuously.

Recycling:

Recycling means to recover for other use a material that would otherwise be considered waste. The popular meaning of ‘recycling’ in most developed countries has come to refer to the widespread collection and reuse of various everyday waste materials, such as newspapers and drink bottles.

They are collected and sorted into common types so that the raw materials from these items can be used again to create new products. In many areas, material for recycling is collected separately from general waste using dedicated bins and collection vehicles. Other waste management processes can recover materials from mixed waste streams.

In developed countries, the most common consumer items recycled include aluminium beverage cans, steel, food and aerosol cans, HDPE and PET bottles, glass bottles and jars, paperboard cartons, newspapers, magazines, and cardboard. Other types of plastic (PVC, LDPE, PP, and PS) are also recyclable, although these are not as commonly collected. These items are usually composed of a single type of material, making them relatively easy to recycle into new products. The recycling of complex products (such as computers and electronic equipment) is more difficult and costly, due to the separation and reprocessing required.