In this article we will discuss about the process of anaerobic digestion which is used to treat wastewater.

Meaning of Anaerobic Digestion:

Anaerobic Digestion (AD) is a biological process similar in many ways to composting. It is a natural treatment process and, as in composting, bacteria break down organic matter and reduce its bulk or “mass “.

Anaerobic digestion is a complex biochemical reaction carried out in a number of steps by several types of microorganisms that require little or no oxygen to live. During this process, a gas that is mainly composed of methane and carbon dioxide, also referred to as biogas, is produced. The amount of gas produced varies with the amount of organic waste fed to the digester and temperature influences the rate of decomposition and gas production.

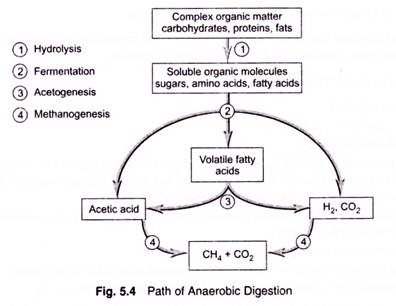

Anaerobic digestion occurs in four steps:

i. Hydrolysis:

Complex organic matter is decomposed into simple soluble organic molecules using water to split the chemical bonds between the substances.

ii. Fermentation or Acidogenesis:

The chemical decomposition of carbohydrates by enzymes, bacteria, yeasts, or molds in the absence of oxygen.

iii. Acetogenesis:

The fermentation products are converted into acetate, hydrogen and carbon dioxide by what are known as acetogenic bacteria.

iv. Methanogenesis:

Methanogenesis is formed from acetate and hydrogen/carbon dioxide by methanogenic bacteria.

The acetogenic bacteria grow in close association with the methanogenic bacteria during the fourth stage of the process. The reason for this is that the conversion of the fermentation products by the acetogens is thermodynamically only if the hydrogen concentration is kept sufficiently low. This requires a close relationship between both classes of bacteria.

The anaerobic process only takes place under strict anaerobic conditions. It requires specific adapted bio-solids and particular process conditions, which are considerably different from those needed for aerobic treatment.

Why are we Excited about Anaerobic Digestion just now?

A remarkable combination of recent technical, political and regulatory factors is starting to propel AD forward toward the mainstream.

Some of these factors are:

(i) Rising oil prices:

Suddenly traditional energy sources are so much more expensive. In the past AD was a much more expensive energy source, and to be honest it remains so when all capital spend up-front is considered, but the gap is narrowing toward mainstream take-up of AD, and fast.

(ii) Farm waste requires better management:

As from June 30,2006 the EU Waste Management rules apply to farming and agriculture, and their historical exemption has been removed.

(iii) Organic waste must be diverted from landfill:

This is the result of the EU landfill Directive and AD is an excellent technology for organic waste landfill diversion.

(iv) The demand for new sustainable technologies investment opportunities powered by individuals but increasingly manifested in actions and investments by large companies and big investors. (January 2007 has seen the big supermarkets in the UK talking about using renewable energy technologies in their stores, including Anaerobic Digestion).

(v) Rising demand for renewable fuels and bioenergy:

This includes government targets and incentives to Anaerobic Digestion which the United Kingdom and other governments provide to help them meet the targets.

(vi) The availability of carbon credits to those who avoid carbon dioxide emissions:

The developing world has been able to apply and obtain CER credits for nearly two years, and under the new US proposals (including the Methane to Markets project) it seems that the US may be soon paying carbon subsidies even to the developed nations where carbon emissions reductions are achieved in carbon neutral, and negative projects such as Anaerobic Digestion.

Is this a new Process?

When the term “anaerobic” is used it may seem to the non-technical among us that science has conjured up a new form of digestion. Of course, this is not the case.

Methane bacteria are everywhere, and always have been. They not only occur widely in the bottom sediments of ponds, marshes, lakes and swamps, but much closer indeed in the intestinal tracts of man and many animals (especially cattle and other herbivores). Methane bacteria are usually found in association with sulphate-reducing bacteria.

Why are they all about us, you might ask? The reason is that they are scavengers, removing the decomposition products of other anaerobic bacteria and converting them to a mixture of carbon dioxide and methane gas. This mixture is that we call “biogas”.

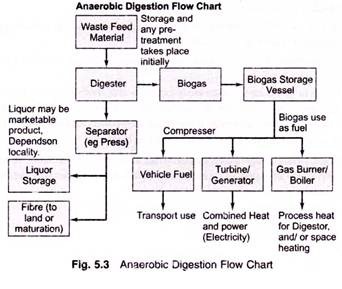

What happens in an MSW Anaerobic Digestion Plant?

Refuse Collection Vehicles (RCVs) deliver the collected waste to the plant and the degree of sorting then applied varies. Source separated garden and food waste often can go straight into the process, but mixed residual (‘black bag’) waste needs sophisticated sorting mechanically to remove the non-biodegradable contaminants. The plant in which this sorting is done is called a Materials Recycling Facility (MRF).

Sorting may involve screens, rotating drums for segregation, air classifiers, and powerful magnets. The organic waste fraction is then shredded and usually mixed with water. The waste and water slurry is then pumped into a sealed vessel where it is heated and stirred where it stays for up to about 3 weeks. This is known as the digestion or fermentation stage.

During this period the bacteria digest the waste and create a gas comprising of about sixty percent methane with the remainder being mostly carbon dioxide. This can be used as the source of the heat energy to warm the digestor(s), and there is usually sufficient methane left over to power an electricity generation set.

The process is normally continuous and filling and removal of the treated material takes place simultaneously. The output takes two forms. There is a solid digested material (digestate) which is often pressed to reduce the water content. The solid digestate is fibrous and can be used as a soil improver once it has been further matured usually by being placed in piles to aerobically compost, further reducing its weight, for about two weeks.

The digestate is very similar to compost once it has stood in the air for this period.

Unfortunately, even for most source segregated wastes there will be foreign matter, especially plastics etc., in the matured digestate. So, additional sorting is usually be required to remove contaminates before it can be used, and the most common is the use of a small mesh size screen.

The liquid fraction can be re-circulated back into the process, but in almost all process designs some excess water is generated. And depending on the removal of, or avoidance of, the presence of possible infectious agents from the feedstock, this can be used as a fertiliser. If the waste source was classed as contaminated (e.g., food waste) and the waste is not then pasteurised within, or after, the digestion stage the resulting liquid product cannot be used on the land and has to be disposed of to sewer.

What is the Chemical Equation?

The reactions involved can be represented as follows:

CO2 + 4H2 → CH4 + 2H2O (e.g., Methanobacterium bryantii)

CH3COOH → CH4 + CO2 (e.g., Methanosarcina barkeri)

Syntrophic bacteria such as Syntrophobacter wolinii and Syntrophomonas wolfei provide the methane bacteria with their food supply via the reactions which convert propionate and other volatile acids into acetic acid and hydrogen gas.

Other supplies of food to the methanogens are other anaerobic (food decomposing) bacteria which decompose complex organic substances into volatile fatty acids.

Thus, methane bacteria provide the ultimate waste disposal system for a whole community of bacteria that grow together to provide the biological basis for what has become known as the “anaerobic digestion process”, which occurs naturally in sludge digesters at sewage works and in damp putrescible deposits in landfill sites.

Methane production also takes place in the bottom sediments of ponds, marshes, lakes and swamps, and phenomena referred to in old accounts such as the “will-o-the-wisp”, no doubt originate from methane from such sources.

Effectively the anaerobic digestion process has been devised simply to “engineer the inevitable” and allow this natural fermentation to proceed to completion before discharging the fibrous “digestate” to landfill or to a “composting plant” further mixing and decomposition can take place to make the digestate suitable for agricultural, and horticultural applications.

The Purpose of Anaerobic Digestion in MSW Treatment:

The main purpose for Anaerobic Digestion in MSW Treatment has previously been to reduce the bulk (or “mass”) of the material.

The new generations of MSW anaerobic digesters are being promoted with the additional benefits of:

i. Biogas biofuel production; which can be burnt for electricity production etc.

ii. Sanitisation; due the AD Process’ ability to operate at raised temperatures (usually using the biogas produced by the process) during the reaction, to ensure compliance with Animal Byproduct Regulations (ABPR)

iii. Producing a digestate comprising a fibrous material, which can be spread on land, co-dis- posed with compost, or incinerated, and a liquor which (with care) can be used as a liquid fertiliser, but often must be further treated.

The popularity of anaerobic digestion is likely to rise as the demand for biofuel produced to replace fossil fuels increases with rising public awareness of the dangers of climate change.

Anaerobic Decomposition:

A biological process, in which, decomposition of organic matter occurs without oxygen. Two processes occur during anaerobic decomposition. First, facultative acid forming bacteria use organic matter as a food source and produce volatile (organic) acids, gases such as carbon dioxide and hydrogen sulfide, stable solids and more facultative organisms. Second, anaerobic methane formers use the volatile acids as a food source and produce methane gas, stable solids and more anaerobic methane formers.

The methane gas produced by the process is usable as a fuel. The methane former works slower than the acid former, therefore the pH has to stay constant consistently, slightly basic, to optimize the creation of methane. You need to constantly feed it sodium bicarbonate to keep it basic.

Advantages and Disadvantages of Anaerobic Treatment:

The principal advantages and disadvantages of anaerobic treatment when compared with the aerobic equivalent processes are listed.

Advantages of Anaerobic Treatment:

(i) Less energy required

(ii) Less biological sludge produced

(iii) Lower nutrient demand

(iv) Methane production- Providing potential energy source with possible revenue both from sale of the energy, and benefit from government tax, and (Kyoto agreement) CDM etc., payments arising from renewable fuels/non-fossil fuel incentives

(v) Methane production- Anaerobic digestion contributes to reducing greenhouse gases by reducing demand for fossil fuels

(vi) Smaller reactor volume required

(vii) Biomass acclimatisation allows most organic compounds to be transformed

(viii) Rapid response to substrate addition after long periods without feeding

(ix) End product can be potentially saleable products biogas, soil conditioner and a liquid fertiliser.

(x) Process more effectively provides sanitisation/removal of diseases.

Disadvantages of Anaerobic Treatment:

(i) Longer start-up time to develop necessary biomass inventory

(ii) May require alkalinity and/or specific ion addition

(iii) May require further treatment with an aerobic treatment process to meet discharge requirements

(iv) Biological nitrogen and phosphorus removal is not possible

(v) Much more sensitive to the adverse effect of lower temperatures on reaction rates

(vi) May need heating (often by utilisation of process gas) to achieve adequate reaction rates

(vii) May be more less stable after ‘toxic shock’ (e.g., after upsets due to toxic substances in the feed)

(viii) Increased potential for production of odours and corrosive gases.

(ix) Hazards arise from explosion. (In the EU, such additional Health & Safety Regulations as the ATEX Directive, and possibly also Gas Institute Regulations will require various compliance measures to be applied for AD.)

(x) Anaerobic treatment is not effective for treatment of methanogenic landfill leachate, it may (rarely) be efficacious for the early stage leachate production period while the waste is still acetogenic.

Biomethanation:

Biomethanation is a general term for all the biological methods used for the production of methane biogas.

The methods available for biomethanation are:

1. Anaerobic Digestion in digestors

2. Methanogenesis in landfills.

3. Up flow Anaerobic Sludge Blanket Process (UASB).

Biomethanation by Anaerobic Digestion:

There are a variety of different Anaerobic Digestion (AD) technologies available. However, there is a new role for these processes as energy generators.

Historically, the most accomplished in AD Technologies have been the Chinese at the most simple low technology (mostly community and domestic) level — usually for gas supplies for cooking from sewage using AD.

Nowadays, in the large scale commercial Municipal Solid Waste (MSW) to energy market, there are an increasing number of European Companies emerging which have developed AD for MSW, over the past 10 to 20 years, who use variations of the AD process.

Potential Feed Anaerobic Digestion Plant Feed Materials:

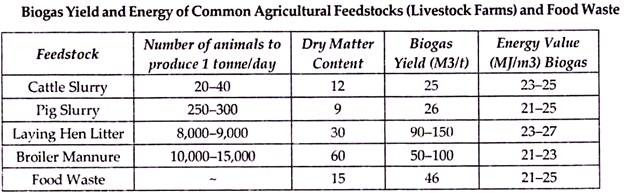

Another question posed is what is the biogas yield which can be expected from agricultural wastes and this is also answered below:

(i) Dairy Farm and piggery etc., waste slurries

(ii) Dairy Product and other Food Processing wastes

(iii) Household Food Waste with or without Green Waste

(iv) Brewing Industry effluents and wastes

(v) Supermarket Waste

(vi) Municipal Solid Waste from Kerbside collections of Green Waste

(vii) Municipal Solid Waste from Kerbside collections of Green Waste and Kitchen Waste

(viii) Catering Industry Wastes

(ix) Organic Market Wastes

(x) Sewage Treatment Works sludges

(xi) Silage/ley crops (may be included and kept in storage to provide a feedstock for use to augment feed during winter seasons when the availability of other feed materials will be reduced)

(xii) Other organic wastes available locally from other process industries.

Anaerobic Digestion Design Biogas Digester:

The terms anaerobic digestion design and biogas digester are synonymous, as is biomethanation design. However, the term Anaerobic Digestion Plant design is used as a more generic term.

This is due to the fact that the term “biogas” suggests that the plant’s primary purpose will be to produce biogas (methane), and there are many anaerobic digestion plants both in use today and historically that have not been installed primarily to produce and utilise biogas (methane for electricity generation, biofuel for transport vehicles, LPG for cooking and heating use etc.).

Anaerobic digestion design also encompasses plants which are primarily designed to:

1. Treat an effluent (as in industrial effluent treatment) to a quality which will allow it to be discharged to a sewer or to a watercourse according to the requirements of the site owner and the regulatory authorities;

2. Treat the secondary (sludge) by-product from a water treatment process to reduce volume, sanitise, and permit final disposal (e.g., to land); as in the digestion of sludge created during the popular (aerobic) activated sludge sewage treatment process;

3. Treat Solid Waste (as in Municipal Solid Waste (MSW)) to primarily help meet local government targets (especially within the European Union (EU)) where strict targets must be achieved by member states to divert the overall tonnage of MSW away from landfill, and also to reduce still further the amount of organic/biodegradable content within the waste which is sent to landfill.

4. It is only since about 2003 in Europe, but possibly a century earlier in China, that the creation of biogas has been a viable function of anaerobic digestion plants. The reason that AD biogas has now become a valued commodity is that fossil fuel sources of methane gas have risen so much in price that (with some encouragement from government grants and tax breaks) biogas methane can be cheaper.

5. Biogas is, when scrubbed and pressurised, equivalent in composition and broad calorific value to the fossil fuel known as Liquid Natural Gas (LNG) and at lower pressure can double for Natural Gas in town and city gas supply pipelines.

6. Just as the primary purpose, and scale, of Anaerobic Digestion Plants is very diverse so are the processes which have been developed to meet these challenges. Many processes are similar in principle, but do vary substantially according to the primary purpose and environmental, plus economic and political drivers.

Review:

The aerobic, anoxic, and anaerobic process helps prepare the waste for decomposition by attacking the organic compounds that in wastewater. In aerobic decomposition the only microorganisms that can survive are the aerobic organisms. In anoxic decomposition the microorganisms use chemically combined oxygen that is found in nitrite and nitrate.

In this process the organisms consume the organic matter to help support their life functions. In the first stage of anaerobic decomposition, acid forming bacteria use the organic matter for food which produces volatile gases, acids and facultative organisms. Second stage methane formers use the volatile acids as a food source and that produces more gases. This gas can be used as fuel.